Achieving Optimal Performance for the Competition Season

Maintaining Gliding Performance with little Effort

In addition to doing the necessary maintenance and technical work on their sailplanes for the coming season, many competition pilots also carry out performance optimization work at the same time. This way the outstanding performance of modern sailplanes can be easily retained.Very significant factors in this are a properly functioning blowhole system on the bottom of the wing as well as good quality wing surfaces. With the airfoils used in our sailplanes, the blowhole technique is the most effective way to prevent formation of harmful separation bubbles. That is why it really pays off to have this system working perfectly at the beginning of the season.

Pay attention to the following details:

NACA inlet ducts on the bottom of the wing

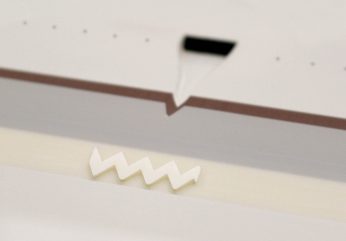

The blowing out of air from the ailerons and flaps is achieved by air entering at the so-called NACA inlets. These inlets are only effective if the zig-zag tape immediately in front of the inlet is properly positioned and in good condition. Normally they consist of two 28 mm wide pieces positioned on top of each other. Exact information can be found in the maintenance instructions attached to the Maintenance Manual of each sailplane. The inlets must not be dirty or blocked.

Blowholes

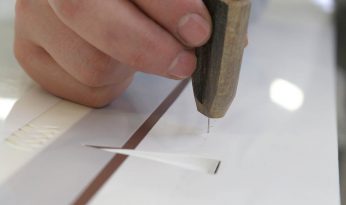

After being sucked in, the air is blown out again through the small blowholes in the aileron and flaps. It is therefore important that these blowholes are not partially or completely blocked. The simplest way to clean them is to push an exactly 0.6 mm (0.024 in.) diameter drill bit through each hole by hand. The use of a small electric drill or Dremel tool is not recommended.

Note: Since an aileron or flap can be destroyed by even low pressures, the testing of the blow holes with pressurized air is not permitted.

In some areas, e.g. in the area of the control drives or in the very narrow outer parts of the aileron, the installation of blowholes is not possible. Instead, zig-zag tape is installed in such areas. Exact information can again be found in the maintenance instructions attached to the Maintenance Manual of each sailplane.

Zig-zag tape

Loose zig-zag tape must be replaced. Tapes with raised or flattened teeth should also be replaced.

Pointers for Care

During wing surface maintenance work such as buffing or polishing, care should be taken not to damage the zig-zag tape or block the blowholes. This can be prevented by taping them over with thin tape while polishing.

Photos: Manfred Münch